with robots,

make Our future

News

About

-

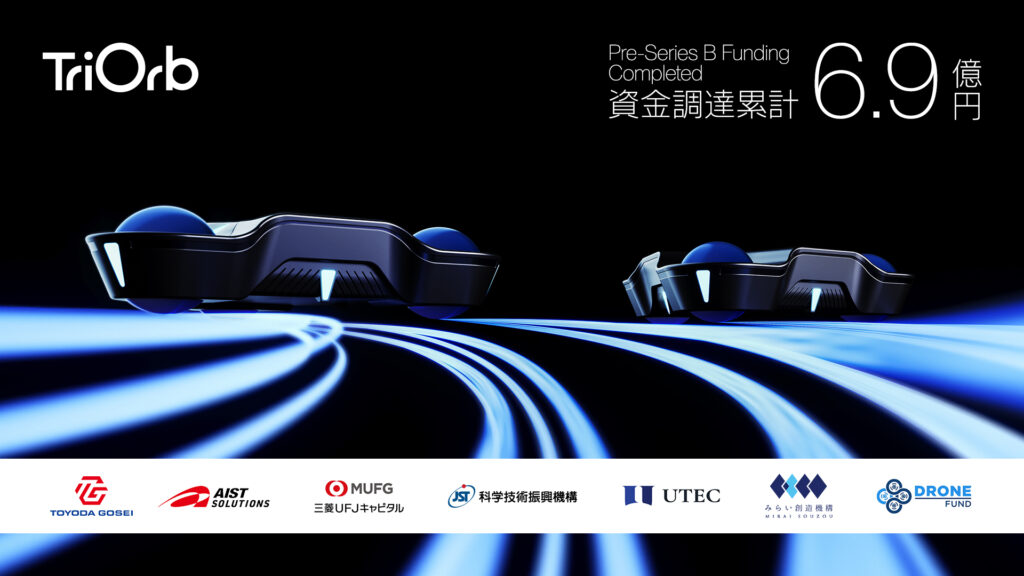

TriOrb is a robotics startup from a Japanese national research institute, specializing in autonomous mobility. Founded in 2023, we develop ball-driven omnidirectional mobile robots (Ball-Driven System) to redefine mobility and transform production systems.

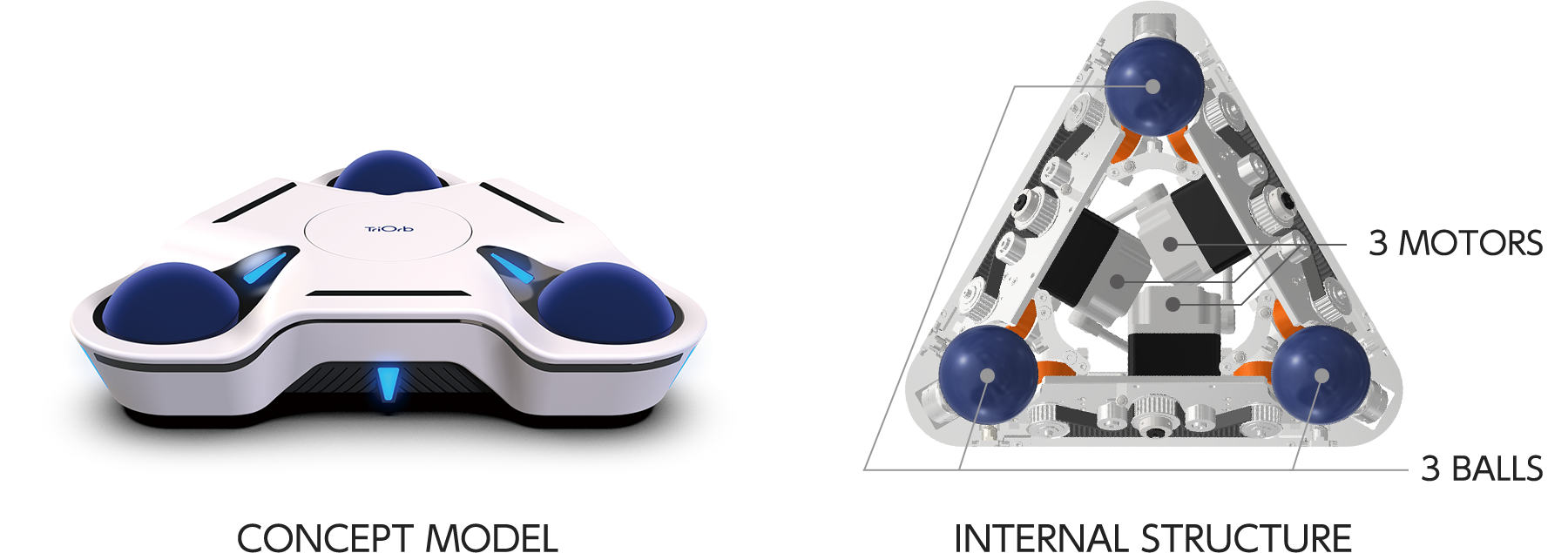

Our patented drive mechanism (researched since 2008) enables millimeter-level precision, compact design for tight spaces, 800 kg payload capacity, step-over ability, and multi-robot coordination.

Seamless integration with mobile manipulators and production equipment enables flexible and reconfigurable manufacturing environments. We work with major Japanese automotive OEMs and Tier 1 suppliers, and are expanding into the U.S. market through PoC projects and strategic partnerships. -

Company Name TriOrb Inc. Location 【Japan Headquarters】

Kitakyushu Innovation Center, 16 Miyoshino-machi, Yahatanishi-ku, Kitakyushu, Fukuoka, Japan

【US Expansion Hub at Newlab】

Detroit 2050 15th St, Detroit, MI 48216Business Activities We specialize in the robot development, menufacturing, sales, maintenance, as well as software development, sales, and maintenance. Establishment February, 2023 Share 100 million yen (as of end of September 2025) Representative CEO Shuichi Ishida Number of Employees 5 Executives (including 3 external directors), 30 employees (23 full-time employees) (as of end of September 2025)

Equity &

Financial Partners

Technology

-

An entirely new high-performance ball-driven omnidirectional locomotion mechanism that can move freely in all directions with a simple configuration of three balls and three motors.

Team

-

CEO

ISHIDA Shuichi

Doctor of Engineering

He holds a doctoral degree in Engineering from the Graduate School of Bioscience and Biotechnology at Kyushu Institute of Technology. With a decade of dedicated research experience at AIST, Japan's premier national research institution, he specialized in the evaluation of production systems and processes for the manufacturing industry. Notably, he served as the team representative in the prestigious global competition, RoboCup Soccer, where he led his team to secure first place in the Japan tournament and an impressive second place in the world tournament's technical category.

-

COO

SHIMANO Satoshi

After graduating from the Faculty of Law at Kyushu University, he joined Mitsubishi UFJ Bank, one of Japan's largest commercial banks. He worked in sales department for 7 years and then transitioned to head office planning for 8 years. His main involvement revolved around initiating new business ventures and leading the development of financial products.

-

Independent Director

SAKAMOTO Noriaki

Noriaki graduated from the University of Tokyo (Econ dept) and joined Ministry of Economy, Trade and Industry in 2003. After working METI for 5 years, he was appointed vice president of his family business. Noriaki graduated Columbia University (MBA). Prior to joining UTEC, Nori worked for McKinsey & Company as an engagement manager where he specialized in corporate finance and SCM.

Apart from UTEC, he is currently General Manager of Planning Department of Japan Venture Capital Association (JVCA). -

Independent Director

TAKAHASHI Ryohei

Doctor of Engineering

After graduating from the Faculty of Economics at Kyoto University, he joined Mitsubishi Corporation, where he was involved in business development for cloud services targeting the construction industry. After leaving the company, he ventured into entrepreneurship by establishing a medical university spin-off venture and successfully achieved mergers and acquisitions with major corporations. Additionally, he worked at a US-based strategic consulting firm, specializing in formulating digital strategies. He holds a degree from the Innovation Science Department at Tokyo Institute of Technology, School of Environment and Society.

About Sales Performance

Please tell us about your sales performance.

Since our founding in April 2023, we have successfully delivered products to a major semiconductor manufacturer in the first six months, with plans for over ten more deliveries in the near future.

Our customers span various industries, including automotive, semiconductor, printing, agricultural machinery, aerospace, machine tools, general contractors, and overseas companies. We have received significant interest from companies with manufacturing facilities that are actively promoting automation.

About Robot Implementation

What is the price of the robot?

The price varies depending on equipment specifications and configuration. We will provide a quote tailored to your requirements, so please feel free to contact us first.

Is it possible to conduct driving tests at the site where implementation is planned?

Yes, it is possible. We will conduct tests in the most suitable manner after confirming the site environment and your requirements. Please contact us for details.

Is it possible to view the actual unit?

Yes, it is possible. You can view the actual unit and see a demonstration at our Yahata Office or Rinkai Office. Please let us know your preferred date and time through our inquiry form.

Can it be used overseas?

Currently, we are primarily deployed in Japan, but we also have implementation achievements overseas. If you are considering use overseas, please contact us.

About Robot Specifications and Functions

How much weight can it carry?

The standard model can carry up to 300kg per unit. As a customization achievement, we have also handled transportation of up to 800kg per unit. Additionally, for all models, you can utilize our "cooperative transport system" where multiple units work together for conveyance.

How long is the operating time?

With the battery provided as an option, continuous operation is 3.5 hours. Battery capacity can also be adjusted according to your usage conditions. Please contact us for details.

Can it be used outdoors?

Basically, it is designed for indoor operation, but outdoor use is also possible depending on the conditions. Please contact us for details.

Can it travel on uneven floors or floors with steps?

Standard specifications allow travel over grooves up to 45mm, steps up to 10mm, and gradients up to approximately 9°. The standard ball diameter is φ100, but we also have production experience with φ140 and φ200. If you require other ball diameters, please feel free to contact us.

Are there safety features such as obstacle detection and emergency stop?

Yes, there are. We offer as options: stopping upon obstacle detection by safety laser scanner, and stopping function upon collision by bumper sensor. We also have production experience with remote emergency stop functions.

What options are available?

Based on our production achievements to date, we offer the following options:

・Lift-up function

・Wireless charging

・Obstacle detection by safety laser scanner

・Collision stop function by bumper sensor

・Remote emergency stop function

How does it recognize position and navigate?

It recognizes the surrounding environment using fisheye cameras mounted in four directions on the robot body. Based on this information, it creates an environmental map using Visual SLAM technology and navigates while estimating its own position.

What is the maximum number of units for cooperative transport?

For autonomous driving, we have implemented cooperative transport with 2 units. For remote control operation, we have completed testing with up to 4 units.

Is it possible to integrate with our in-house upper systems (WMS, MES, etc.) in the manufacturing facility?

On our own, we provide services limited to the hardware (TriOrb BASE) and the realm of autonomous movement software. If you wish to integrate with your in-house system development or combine with your robots, we can collaborate with partner trading companies or system integrators (SIers) to make proposals. Please start by contacting us through the inquiry form, sharing your challenges and needs.

Please provide information on the durability and maintenance of the robot.

TriOrb BASE excels in durability and maintenance. It consists only of consumable items such as balls and belts. The balls, made of urethane material (similar to that used in roller coasters), exhibit very high durability. Additionally, with a simple structure and a low number of parts using commonly available components, maintenance is straightforward.

What measures are taken in case of malfunctions or damage?

As an initial response, we will use phone calls or remote communication to confirm the cause and situation. If the issue cannot be resolved in the initial response, please send the actual equipment to us for further diagnosis. We will then provide a cost estimate for the repair. Repair costs, excluding initial defects, are the responsibility of the customer.Please note that depending on the availability of parts, it may take approximately one month.

C O N T A C T U S