News

We have started joint research with TODA CORPORATION to develop material conveyance equipment

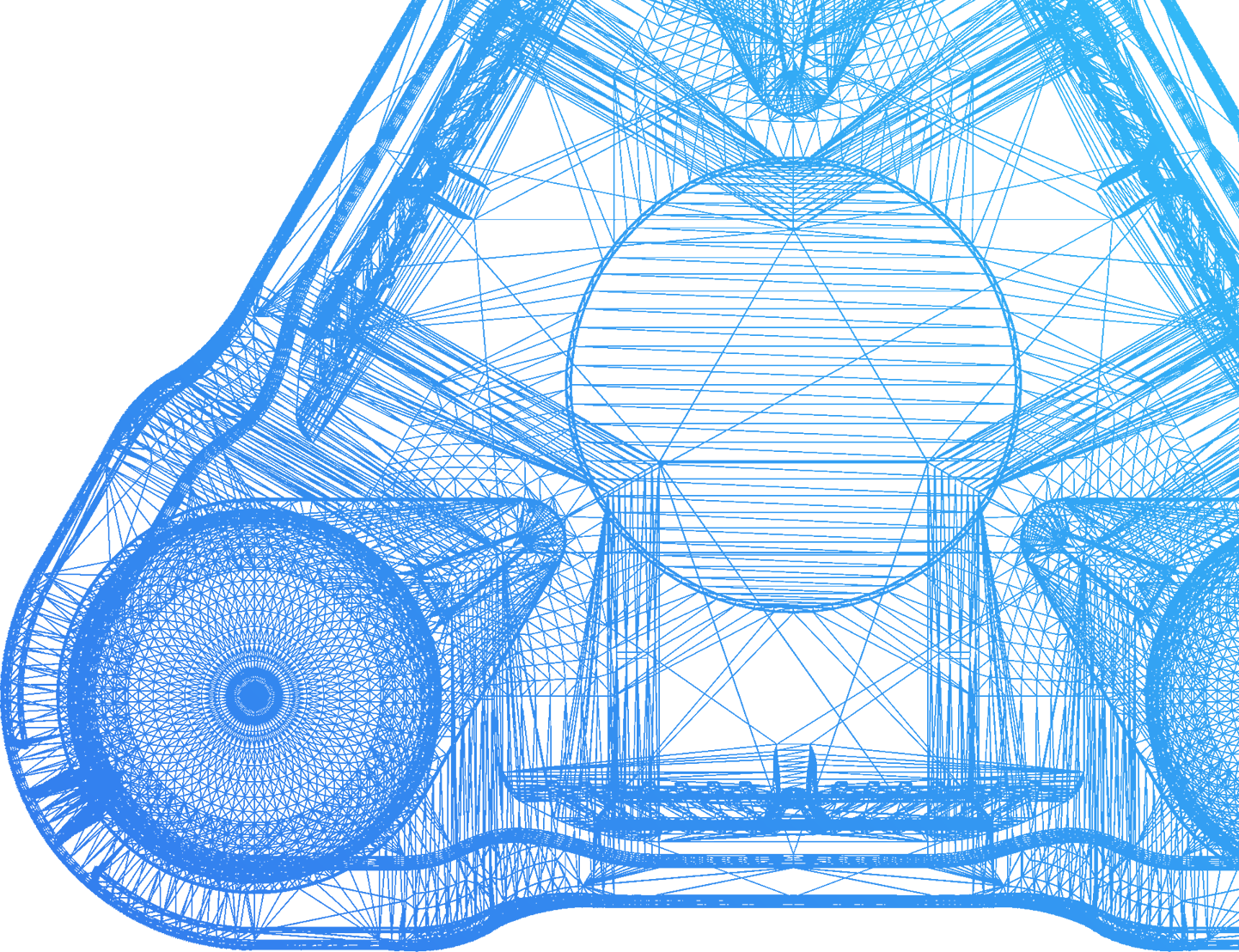

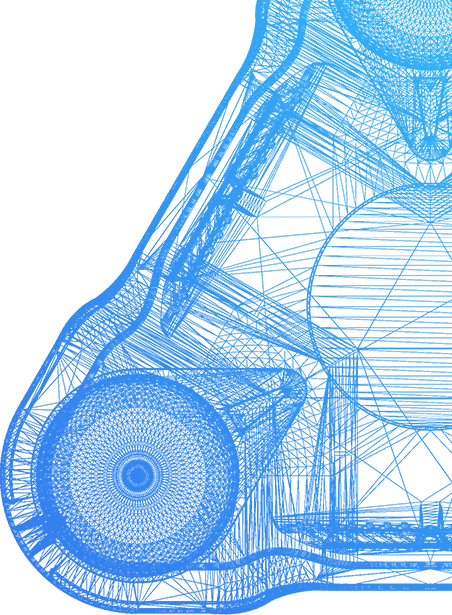

We have signed a joined research agreement with TODA CORPORATION, we are developing a material transport device that can autonomously move at construction sites using an omnidirectional mobile robot (TriOrb BASE) to solve the problem of labor shortage in the construction industry, replace heavy labor with robots, and improve productivity.

When developing mobile robots for construction sites, many attempts have been made to repurpose AMRs (autonomous transport robots), which are used in warehouses, etc., but they have to deal with the challenges unique to construction sites, such as rough driving surfaces and daily changing surfaces. It was difficult to achieve the desired performance in terms of the environment and the efficient movement required in the presence of a large number of materials.

TriOrb BASE has the potential to overcome these issues, and instead of repurposing existing AMRs, we have decided to begin research and development of an autonomous material handling device with the aim of achieving stable running performance even at construction sites. Ta. In the future, TriOrb and Toda Construction will aim for further development by combining technology, knowledge, and resources in the construction industry.

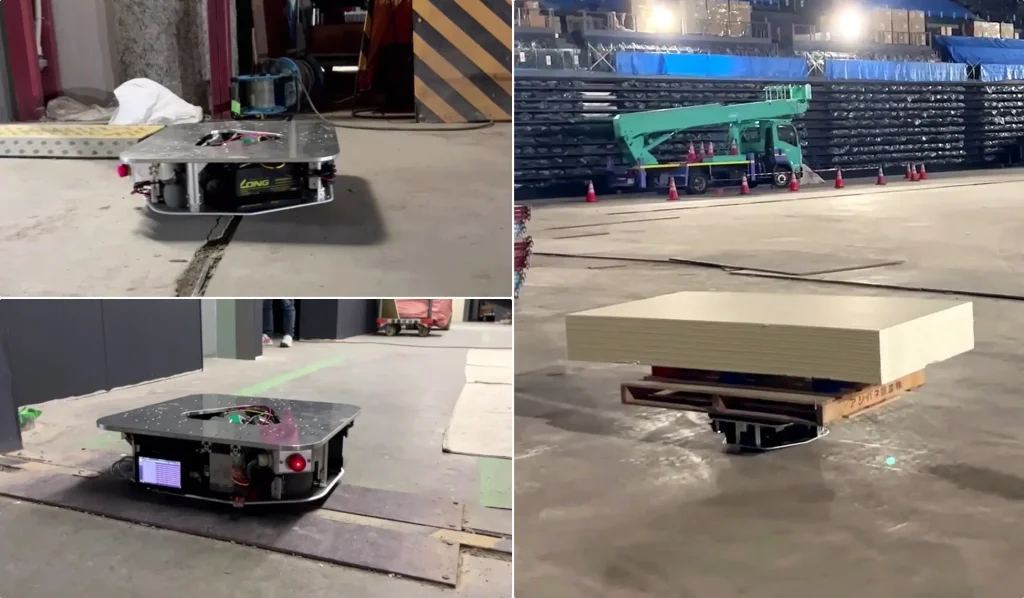

【TriOrb BASE being used in an experiment to transport materials over bumps and ditches and 270 kg】

In order to confirm the basic performance of TriOrb BASE at construction sites, verification experiments were conducted using typical disturbances (steps, ditches) and 270 kg load weight, which are issues at construction sites. Based on the basic data obtained from the experiments, hardware modifications will be made to TriOrb BASE to develop an autonomous omni-directional mobile robot that can travel freely under site conditions.

Comments from TODA CORPORATION

Currently, when building materials and equipment are brought into a construction site, unloaded from the delivery vehicle, lifted to the destination floor by construction elevator, and moved to the designated position after arrival at the destination floor the industry typically uses manual labor. While these transportation operations are heavy work and require a large number of manpower, the number of workers in the construction industry is decreasing and aging, causing a growing need for labor-saving operations.

Our company has faced many challenges in the past through repeated trials. We have high expectations for TriOrb BASE’s portability, precise mobility, and advanced control functions to solve these problems. We aim to further improve productivity at construction sites by combining TriOrb’s robot technology with our own construction site technology, knowledge, and resources.

-

- TriOrb Secures $1.7M in Pre-Series B Funding, B...

On September 30, 2024, TriOrb successfully raised $1.3M in a Pre-Seri…

-

- TriOrb Selected for the “J-Startup KYUSHU...

We are proud to announce that TriOrb has been selected for the "J-Sta…

-

- TriOrb Selected for ” Amazing 100 Venture...

We are excited to announce that TriOrb has been selected for the Week…

C O N T A C T U S